Waterproof Plywood

Waterproof Plywood Specification

- Surface Finish

- Matte Finish

- Glue Type

- Phenolic Resin

- Thermal Conductivity

- 0.13 W/(mK)

- Usage

- Indoor and Outdoor Furniture, Construction, Flooring, Packaging, Boat Building

- Grade

- BWP (Boiling Water Proof) / IS 710

- Size

- 8 ft x 4 ft (2440 mm x 1220 mm)

- Core Material

- Gurjan Hardwood

- Feature

- Water Resistant, Termite Proof, High Strength

- Formaldehyde Emission Standards

- E1

- Back

- Hardwood Veneer

- Tolerance

- 0.2 mm

- Face

- Smooth Hardwood Veneer

- Water Absorption

- <1% after 24 Hours Immersion

- Material

- Hardwood

- Plywood Type

- Waterproof Plywood

- Thickness

- 12 mm

- Glue

- Phenol Formaldehyde

- Load Capacity

- High

- Moisture Content

- Less than 10%

- Minimum Order Quantity

- 50 Sheets

- Application

- Doors, Partitions, Wall Paneling, Shelves

- Screw Holding Capacity

- Excellent

- Number of Plies

- 13 Plies

- Bending Strength

- High

- Environmental Standard

- Complies with IS 303/IS 710

- Fungal Resistance

- Yes

- Edge Type

- Square Edge

- Fire Resistance

- Available on Request

- Manufacturing Technique

- Hot Pressed

About Waterproof Plywood

Owing to our expertise in this domain, we have been able to manufacture, trade and supply our clients a broad spectrum of Waterproof Plywood. This plywood is manufactured under the supervision of highly knowledgeable professionals using optimal grade wood and cutting-edge machinery. Available in various designs, dimensions and textures, the offered Waterproof Plywood is extremely appreciated in furniture industry owing to its features like unblemished finish, high strength, termite resistance and durability.

Superior Performance for Critical Applications

Engineered with 13 plies and hot pressed for stability, this waterproof plywood excels in screw holding and bending strength. The use of quality Gurjan hardwood ensures reliable core integrity, while the phenolic resin glue provides advanced water resistance, making it ideal for construction, furniture, and boat building wherever moisture protection is paramount.

Reliable Moisture and Fungal Resistance

Boasting less than 10% moisture content and resisting both termites and fungi, this plywood offers peace of mind in damp environments. The waterproof construction, certified to IS 303/IS 710 standards, makes it well-suited for applications where long-term durability and hygiene are non-negotiable, supporting both indoor and outdoor installations.

Versatile and Environmentally Compliant Solution

Designed for versatility, this plywood meets E1 formaldehyde emission standards, ensuring safe use in homes and commercial spaces. Its square edges and matte finish deliver clean aesthetics, while its high load capacity and excellent water absorption rating (<1% after 24 hours) make it appropriate for shelving, wall paneling, partitions, and more.

FAQs of Waterproof Plywood:

Q: How is waterproof plywood manufactured to achieve high strength and water resistance?

A: Waterproof plywood is made using a hot press technique, bonding 13 plies of Gurjan hardwood with phenol formaldehyde resin. This method ensures a robust structure, excellent screw holding capacity, and BWP (Boiling Water Proof) qualities, preventing water damage and maintaining stability even under heavy load.Q: What are the benefits of using 13-ply waterproof plywood for furniture and construction?

A: With 13 layers, this plywood offers superior load capacity, high bending strength, and remarkable fungal and termite resistance. It provides durability in both indoor and outdoor furniture, flooring, partitions, and even boat building, contributing to long-lasting and reliable installations.Q: When should fire-resistant waterproof plywood be specified for a project?

A: Fire resistance is available on request and is recommended for projects where enhanced safety is critical, such as commercial buildings, high-traffic partitions, or specific indoor applications. Specify fire resistance at the time of order to ensure the plywood meets your projects requirements.Q: Where can this waterproof plywood be used most effectively?

A: This plywood is ideal for doors, wall paneling, partitions, shelves, furniture, construction elements, outdoor flooring, packaging, and boat building. Its compliance with IS 303/IS 710 standards and high water resistance make it suitable for environments exposed to moisture or varying temperatures.Q: What process ensures the plywoods environmental and health compliance?

A: Manufactured to rigorous standards, this plywood complies with IS 303/IS 710 and E1 formaldehyde emission levels. The use of phenolic resin glue and carefully sourced hardwood ensures both environmental safety and minimal volatile emissions, making it suitable for residential and commercial interiors.Q: How can customers order waterproof plywood and what is the minimum quantity?

A: Interested buyers in India can order directly from the manufacturer, supplier, or trader. The minimum order quantity is 50 sheets, each measuring 8 ft x 4 ft. Bulk supplies can be tailored for large construction, furniture, or industrial projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plywood Category

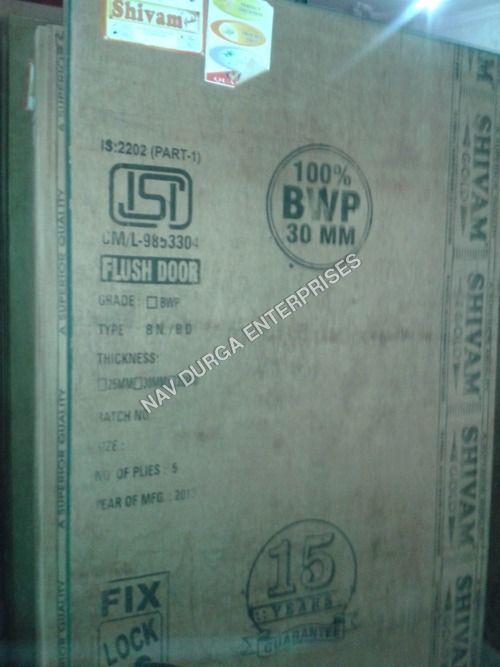

Flush Board

Material : Other, Wood and Plywood Composition

Thickness : 30 mm

Water Absorption : Low

Feature : 100% BWP (Boiling Water Proof), Other

Usage : Other, Interior and Exterior Door Applications

Size : 30 mm thickness

Rubber Wood

Material : Rubber Wood, Other

Thickness : 18 mm

Water Absorption : <10%

Feature : Other, Durable

Usage : Other, Furniture/Construction

Size : 8x4 ft

Plastic Ply Board

Material : Plastic, Other

Thickness : Varies (e.g. 12 mm 18 mm)

Water Absorption : Minimal

Feature : Other, Water Resistant Durable

Usage : Construction Furniture, Other

Size : Standard Sizes Available

Wooden Plywood Board

Material : Other, Plywood

Thickness : 18 mm

Water Absorption : <12%

Feature : Other, Termite Resistant, Waterproof, Environment Friendly

Usage : Other, Furniture, Construction, Flooring, Partition

Size : 8 ft x 4 ft (2440 mm x 1220 mm)